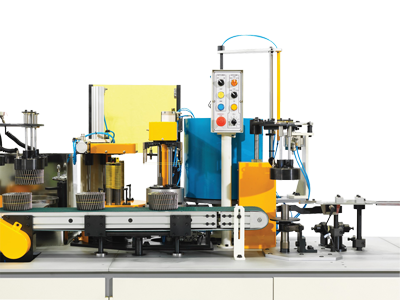

Precision automation for efficient part feeding, orienting, and delivering components, streamlining industrial production processes

Our Jumbo Coilers are expertly crafted to efficiently wind and coil nails, streamlining your production process

Decollators from our collection excel at separating nails from collated strips with precision and speed

Experience a cleaner and safer work environment with our Dustless Dust Collectors, effectively removing dust particles from your nail production

Nail Surface Cleaning machines ensure impeccable nail quality by removing imperfections

High-frequency (HF) Welders are essential for precise and strong nail welding applications

Optimize nail reprocessing with our efficient and reliable Rewelders

Nibless machines provide a smoother nail surface finish by eliminating nibs

Auto Banders automate the banding process, saving you time and labor in production

which is equipped with an inverter can make compressed air with minimum energy consumption

At ZEUS TECHNO INC, we take great pride in providing cutting-edge auxiliary equipment designed to enhance efficiency and productivity in industrial nail production lines. Our comprehensive range of auxiliary machinery complements our high-performance nail manufacturing machines, ensuring a seamless and optimized production process.

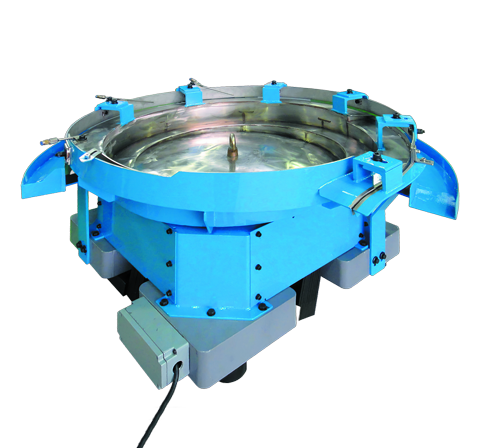

Bowl Feeders boast remarkable versatility, providing a consistent and steady supply of nails to your production line. In the case of RF-36A BOWL FEEDER, this equipment achieves an impressive production rate of up to 4,000 nails per minute. With Neo PWM vibrating systems and precise control over nail diameter and length, our bowl feeders ensure that your nail manufacturing process remains efficient and uninterrupted.

Jumbo Coiler is a dual coiler that significantly reduces handling time, ensuring your production process remains optimized. By attaching JUMBO COILER to wire collating machines, you can achieve precise and seamless coil handling, leading to enhanced overall efficiency.

Decollators serves as an essential recycling equipment for defective plastic strip nails. By efficiently separating nails from plastic scrap, DECOLLATOR allows for the reuse of separated nails, minimizing waste and promoting eco-friendly manufacturing practices.

Dustless Dust Collectors is a powerful vacuum system designed for threading rollers. With a triple-layer filter, DUSTLESS DUST COLLECTOR effectively collects dust and oil, maintaining a clean and safe working environment for your production team.

Nail Surface Cleaning the CR-10 and PHOS-10 serves as a reliable solution to remove oil and dust from the nail surface. With its precise cleaning method and specifications, your nails maintain their pristine quality, meeting the highest industry standards.

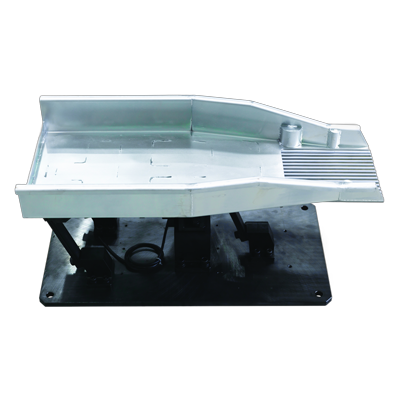

Hoppers optimizes coil handling. Enhance your coil handling process with the HOPPER, which attaches to wire collating machines. By streamlining the handling of coils, you can achieve a more efficient and seamless production line.

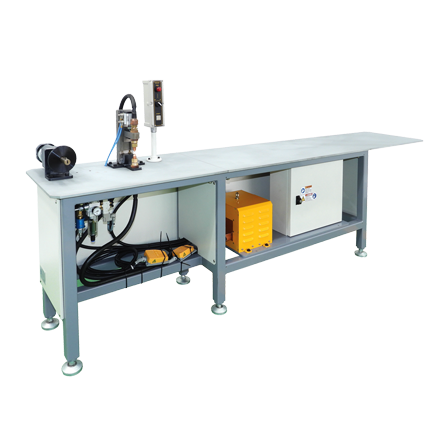

HF Welders with their programmable parameters and selectable multi-channels, offers versatile and constant high-quality welding. Its efficient design ensures superior welding performance, contributing to the production of impeccable nails.

Rewelders serves as a recycling solution for defective coil nails, further promoting sustainability and cost-effectiveness in your production process.

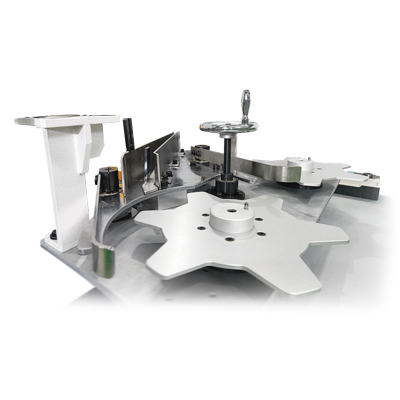

Nibless also known as the vibratory nib separator and conveyor, features a magnetic conveyor and sliding stainless-steel chute, streamlining nail separation and handling.

Auto Banders simplifies the process of banding with its easy-to-find common yellow elastic rubber bands and stable performance, achieving up to 5,000 pieces per minute.

Air Compressor the origin of which is South Korea. It has high quality, ensuring long-lasting performance.